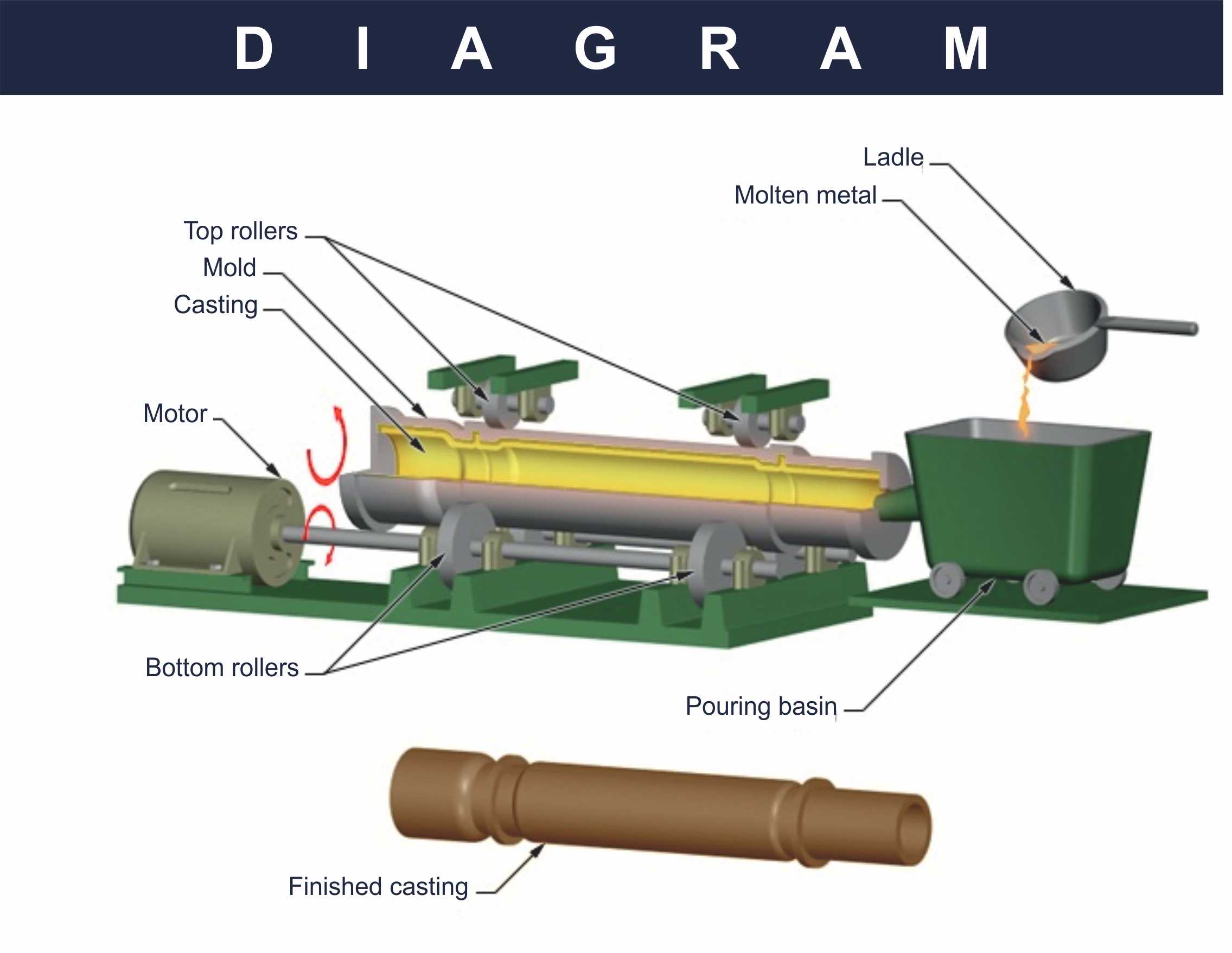

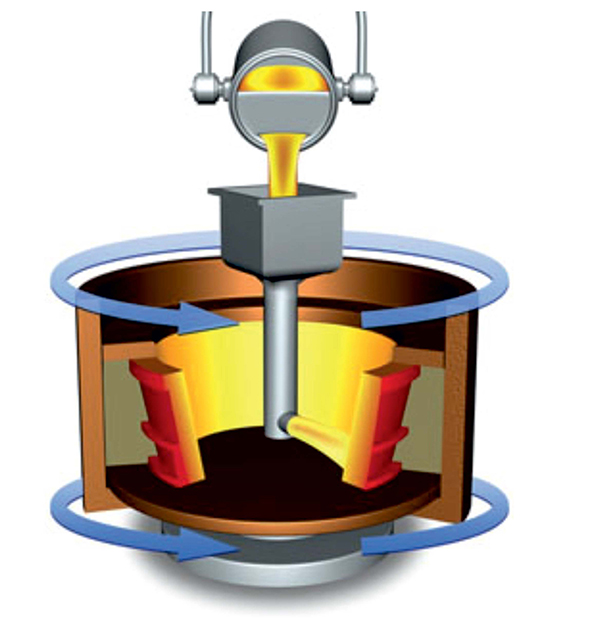

Centrifugal casting consists in manufacturing pieces by allowing the molten metal to solidify while the mold is rotating; thus, the metal adheres to the mold´s walls with the centrifugal force from the machine.

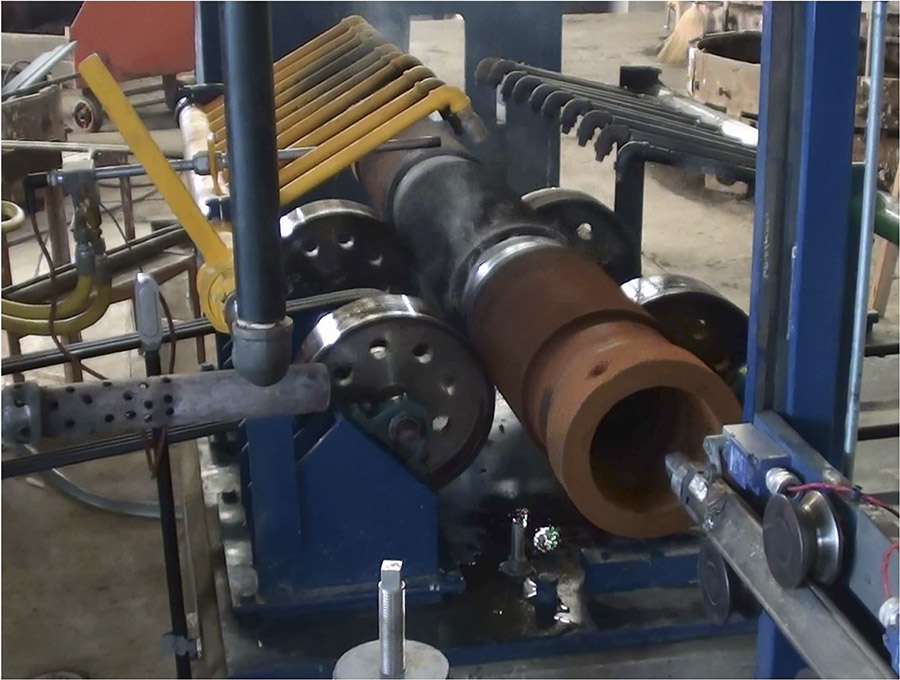

Horizontal machines are preferred for long and thin cylinders, and vertical machines for rings.

PRODUCTS MANUFACTURED USING THIS METHOD ARE RELATIVELY FREE FROM POROSITY,

SINCE THE GRAIN REMAINS TIGHT, HOMOGENEOUS, GAS AND CONTRACTION-FREE,

RESULTING IN A BETTER ALLOY.