We calculate and design the COMPLETE PROPULSION SYSTEM, in addition to the manufacture and machining of its parts.

We provide complete engineering services for the calculation of an entire propulsion system, as well as the manufacture of some of its parts.

Moreover, we give advice for vibrational tests such as torsional, lateral and axial analysis, for a high class approval rating.

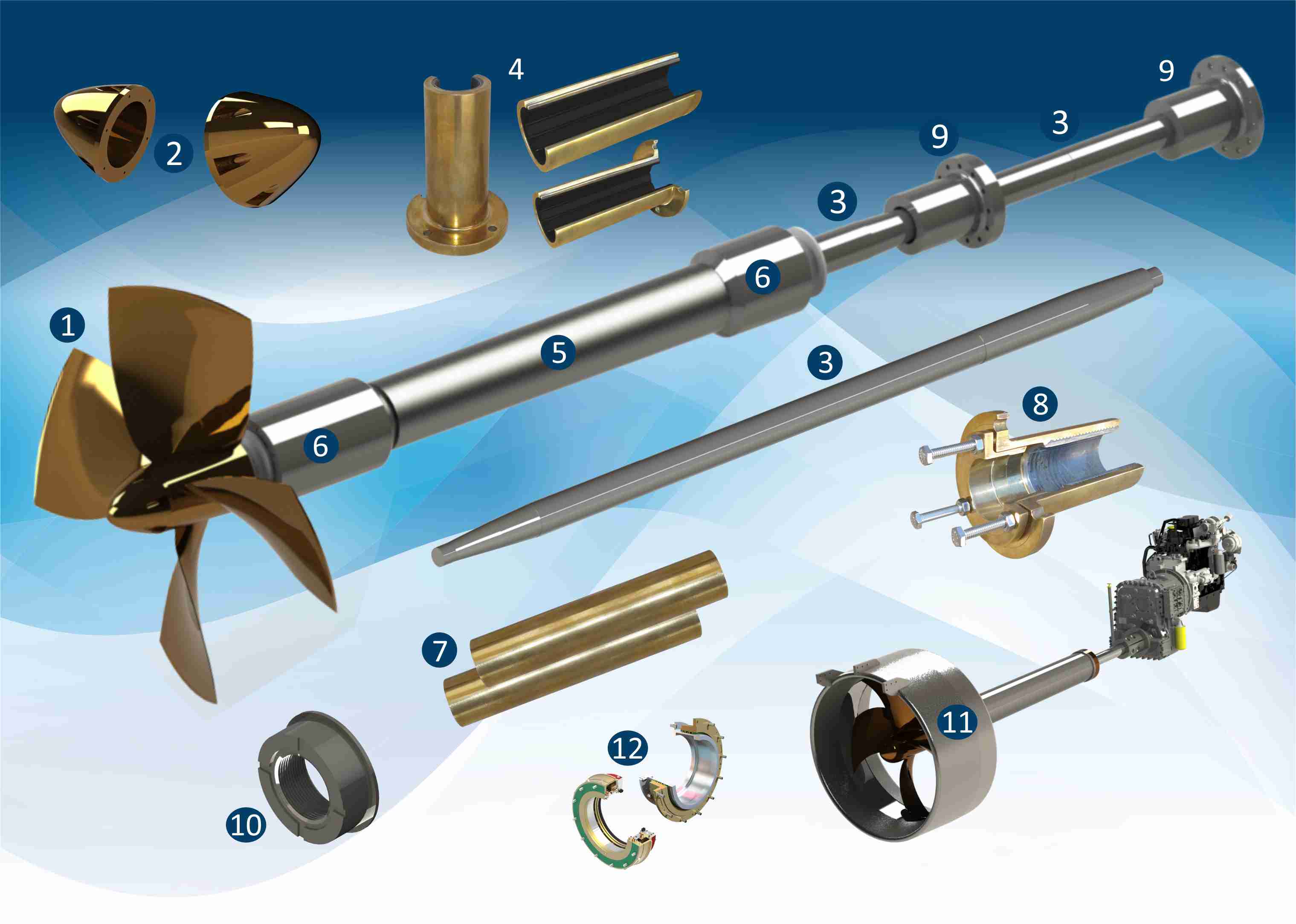

PROPELLER

PROPELLERManufactured in Manganese bronze, NiBrAl or Aqualloy. We offer different styles according to the specifications and needs of the boat. Our engineering department will gladly help you with the calculations and the selection of the most appropriate propeller according to the application.

HYDRODYNAMIC NUT

HYDRODYNAMIC NUT

Manufactured in Manganese bronze, NiBrAl or Aqualloy, designed to allow a better performance by providing a hydrodynamic profile for a better water exit.

SHAFT

SHAFTManufactured in stainless steel or carbon steel depending on the needs and characteristics of the vessel. Completely machined according to the SAE J755 norm or to the customer's specification.

BRONZE-RUBBER BEARING WITH

BRONZE-RUBBER BEARING WITHDesigned to allow smooth and unrestricted rotation of the main shaft for reliable support, ready to install.

STERN TUBE

STERN TUBEIt is the structure that connects the propeller and the engine, where its interior is used as a shaft cooling. Typically supplied with rubber and bronze bushings, designed and built according to customer specifications.

STERN TUBE BEARING

STERN TUBE BEARINGPiece of steel that is used to hold the stern tube and makes connection to the seals, as well as to shelter the bushings that hold the shaft. Also manufactured in bronze and designed according to the customer's specifications.

SLEEVES

SLEEVESManufactured in manganese bronze, it provides the point of contact between the shaft and the bearings, protecting the shaft from wear.

STUFFING BOX

STUFFING BOXUsed to prevent water from entering the hull while still allowing the propeller shaft to turn, made to fit standard SAE J755 shafts or according to customer specifications.

COUPLINGS

COUPLINGS

Manufactured in steel, they provide the point of connection between the shaft and the gear box, and in the case of vessels that require it, the connection between the tail shaft and the intermediate shaft.

COUPLINGS NUTS

COUPLINGS NUTS

Manufactured in stainless steel or carbon steel, depending on the needs and characteristics of the vessel. Completely machined according to the SAE J755 standard or to customer specification.

NOZZLE

NOZZLE

Increase by up to 40% the bollard pull and up to 25% the trawling thrust.

SEALS

SEALS

Manufactured in steel and bronze, they provide the securing between the stern tube and the shaft, and in case of vessels that require it, the connection between the tail shaft and intermediate shafts.