|

In the market, you can find different types of propellers, which are made in series with standard measurements. Something that

stands out is that all our propellers are manufactured and suitable for each client, modifying its dimensions, which allows us to improve the performance of each piece.

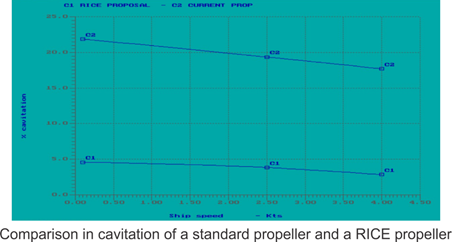

A standard propeller increases the probability of having some type of problem since it does not meet the necessary specifications for the boat to work optimally, increasing problems

such as cavitation, lack of force when increasing the load, generation of vibration and premature wear of parts due to excessive work. This can cause structural propeller failure, engine

overload, and excessive fuel consumption.

A custom piece is created specifically for the ship's unique dimensions and needs.

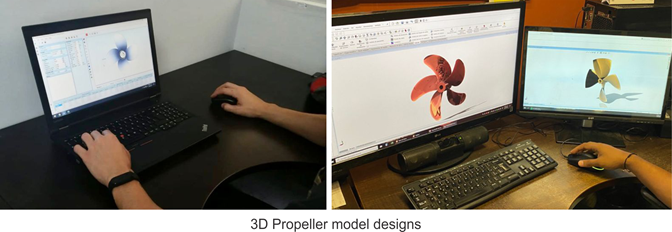

All this, together with a first-class engineering, correct design and highly qualified software, provide a product capable of providing the best power, performance and efficiency when

working, reducing the problems that standard propellers could have, thus expanding the useful life of the piece.

The first step in designing a propeller will be to review the technical information of the boat, as well as the type of service or work it carries out. Once we have the data, the design

engineering is carried out to present proposals to our clients; here the necessary and / or requested factors are modified. By confirming the proposal with the client, the manufacturing

process begins in our plant with its respective monitoring and quality analysis in each part of the production process.

One of our philosophies is to do things right every time, thus guaranteeing a final product of high quality and durability.

|