|

Depending on the personal and professional characteristics of the worker and the nature of the facilities, equipment and circumstances of the workplace, the performance of certain tasks

carries with it some risks that can lead to an accident at work.

The application of safety regulations is intended to prevent accidents and incidents in the workplace. To achieve this, we have studied and proven techniques that can lead to avoiding it.

There are also procedures that, if properly followed by workers and middle managers, ensure that we remain as safe as possible.

It is important to know how to properly handle the machines and tools used in the various jobs, as well as to know the possible risks that each one entails in order to avoid workplace

accidents.

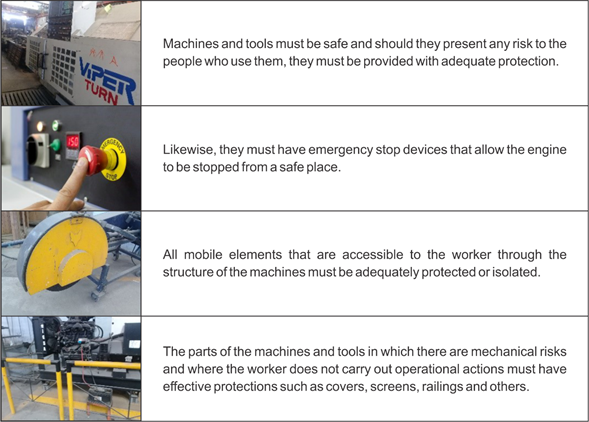

SAFETY CONDITIONS IN MACHINES AND TOOLS

Machines and tools must meet the following safety conditions, among others:

REQUIREMENTS TO BE MET BY THE TOOLS

As for the tools, they must comply with the following requirements, both by the manufacturer and by the worker:

Hand tools must be made of suitable materials and be safe in relation to the operation to be carried out and not have defects or wear that hinder their correct use.

The union between its elements must be firm to avoid any breakage or projection thereof.

To prevent tools from falling and the possibility of cuts or other risks, they must be placed in suitable tool holders, shelves or special selected places.

To transport cutting or sharp tools, use suitable boxes or covers.

Portable tools operated by motive power must be sufficiently protected to avoid dangerous contact and projections.

In tools operated by triggers, these must be protected in order to prevent unintended actuation of the same.

In pneumatic and hydraulic tools, the valves must close automatically when they are no longer pressed by the operator and the hoses and their connections must be firmly fasten to the tubes.

REASONS OF ACCIDENTS AND HAZARDS OF HAND TOOLS

Regarding hand tools, the possible causes of accidents are:

Abuse of tools for any type of operation.

Use of inadequate or defective tools, of poor quality or poorly designed.

Abandonment of tools in dangerous places.

Incorrect transportation of tools.

Hazards of using tools:

Blows, injuries and cuts to the hands by the tool itself.

Eye injuries from particles of objects.

Sprains from overexertion or violent gestures.

RECOMMENDATIONS TO AVOID ACCIDENTS

To avoid possible accidents it is recommended:

Work clothes must be tight. Sleeves should be worn tight at the wrist with elastics, rather than buttons, or rolled up inward.

It is dangerous to work with machines wearing rings, watches, bracelets, neck chains, scarves, ties or any garment that hangs down.

Protect the transmission elements by means of fixed or mobile guards associated with interlocking devices.

Adjustable guards must be adjusted so that only the minimum space is free to carry out the work.

When changing tools, loosening or tying down parts, precautions should be taken against cuts to hands and arms. Always make these operations with the machine stopped.

Use the individual protection equipment necessary for each task: gloves, glasses, apron, boots.

Provide instructions to personnel on the safe handling of these machines.

Review, maintenance and cleaning of the machine and tool systems is always required.

|