|

Welding is a fixing process where two or more pieces of a material are joined, usually achieved through fusion. A contribution material can be added which, when melted, forms a pool

of molten material between the pieces to be welded and, when cooled, becomes a fixed joint called a cord.

The quality of a weld also depends on the combination of the materials used for the base material and the filling material. Not all metals are suitable for welding and not all filler

metals work well with acceptable base materials.

In Rice Foundries we have state of the art equipment and highly trained personnel for the application of welding in the MIG, TIG and SMAW processes, in addition to having ABS-approved

procedures for the MIG welding process for alloys such as ABS-G4 (Aluminum Bronze), ABS-G2 (Manganese Bronze) and Aqualloy (Similar to ABS-G5).

The welding processes that are most used in the industry are:

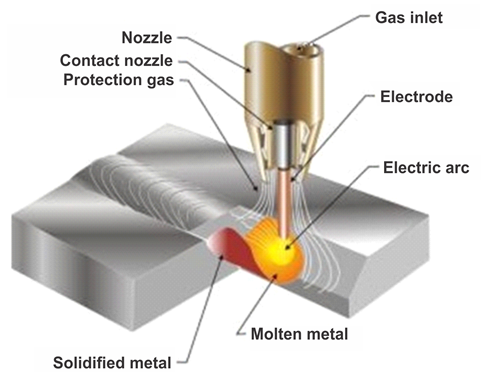

MIG Welding process

Gas metal arc welding (GMAW), also known as metal welding and inert gas or by the acronym MIG (Metal Inert Gas) and MAG (Metal Active Gas), is a semi-automatic process or automatic that uses

a continuous wire feed as an electrode and a mixture of inert or semi-inert gas to protect the weld against contamination.

TIG Welding process

Arc, tungsten and gas welding (GTAW), or tungsten and inert gas (TIG) welding, is a manual welding process that uses a non-consumable tungsten electrode, a mixture of inert or semi-inert gas,

and a separate filling material. Especially useful for welding fine materials, this method is characterized by a stable arc and high quality welding.

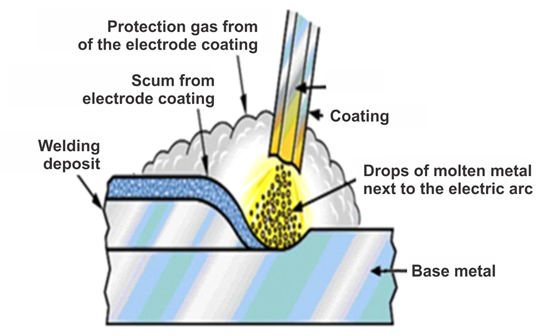

SMAW Welding process

Manual welding with coated electrode (SMAW, Shielded Metal Arc Welding). The electric current is used to create an arc between the base material and the consumable electrode rod, which is

covered with a flux that protects the welding area against oxidation and contamination, through the production of CO2 gas during the welding process. The electrode core acts as a filler

material, making additional filler material unnecessary.

Other processess

Laser welding (LBW)

It is an automated process that uses the heat of a concentrated beam of coherent light to join two materials. The process is used to weld all commercial metals, including Steel,

Stainless Steel, Aluminum, Titanium, Nickel and Copper, and provides high mechanical properties and travel speeds, with low distortion and no slag or splatter.

Submerged arc welding (SAW)

It is a high productivity welding method in which the arc is generated immersed in a fluid. This increases the quality of the arc, since the pollutants in the atmosphere are

displaced by said fluid. The slag that forms the weld generally comes out on its own, and, combined with the use of a continuous wire feed, the welding deposition rate is high.

Tipes of boards

The five basic types of welding joints are as follows:

To test the quality of a weld both non-destructive and destructive tests are used, to verify that the welds are free of defects, have acceptable levels of stress and distortion.

Safety

Welding without proper precautions can be a dangerous and harmful health practice.

The risk of burns or electrocution is significant because many common welding procedures involve an open arc or flame. To prevent them, welders should wear protective clothing, such as

approved footwear, thick leather gloves and long-sleeved protective jackets to avoid exposure to sparks, heat and possible flames. In addition, exposure to the brightness of the weld

area produces a lesion called keratitis due to the effect of ultraviolet light that inflames the cornea and can burn the retinas.

Often, welders are also exposed to dangerous gases and fine particles suspended in the air. The size of the particles in question influences the toxicity of the vapors, since the smaller

particles present a greater danger. In addition, many processes produce carbon dioxide, ozone and heavy metals, which can be dangerous without proper ventilation and protection.

Pictures

|