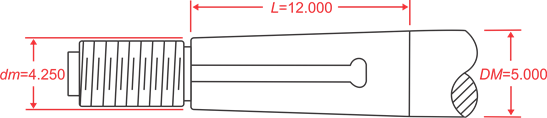

The taper is calculated using the following formula:

Where: D = Large Diameter, d = small diameter, L = Length.

As we can see the taper is 0.0625 inches which complies with the SAE-J755 norm.

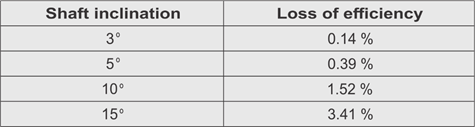

A zero-degree angle shaft (parallel to the water line) is the most efficient, in theory, since the thrust is direct backwards and the water flows to the propeller directly from the bow. In practice, it is very difficult to install it that way and leave enough room for the machine and reduction inside the hull.

The efficiency between a shaft with an angle of 0° and another with 5° is very small, also between 5° and 10°, however, shafts with angles greater than 15° begin to show a significant difference in blade loading of the propeller, this is because the upper blade, as it rotates upward, is currently withdrawing from the water surge, and the lower blade, as it rotates downward, advances directly toward the wake. The result is an uneven load on the blades that can cause vibration and / or cavitation.

|