|

INDUSTRIAL AND MARINE FITTINGS

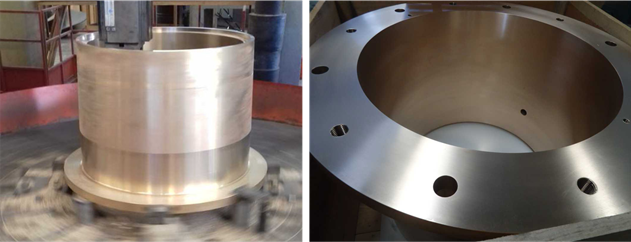

In the industrial field, the most used bronze pieces are those of sacrifice or replacement. These parts are very necessary for the proper functioning of the machinery depending on the

area of action. That is why at Rice Propulsion our commitment is to have a complete knowledge of all the parts that can be used in the different industries, be it cement, sugar, naval,

steel, mining, etc.

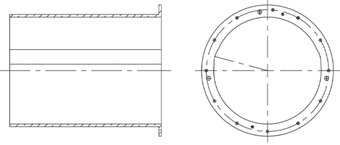

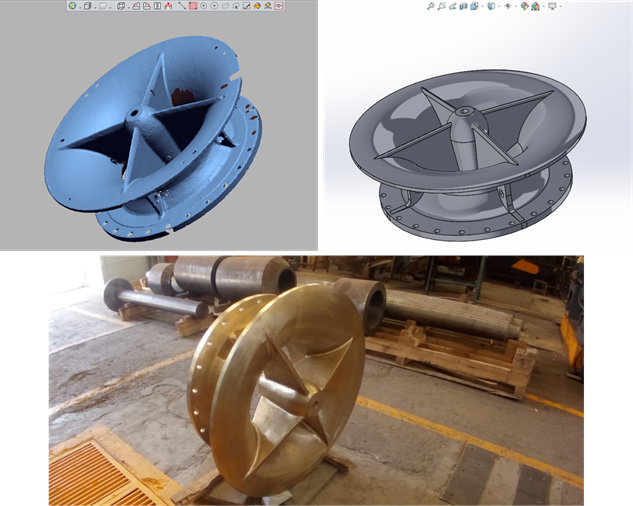

For the design, depending on its type, we use 3D modeling software for the visual and didactic representation of the finished part to be cast or machined. The scope, problems that may

affect short and long term, as well as the tolerances marked according to the certifying houses or those provided by the client in the machinery user manual, are reviewed.

The considerations to be revised are the type of work that the piece will perform, whether it will be heavy work, type of environment to which it will be subjected, material hardness,

elongation, chemical properties, etc. These factors are important in both design and manufacturing.

|

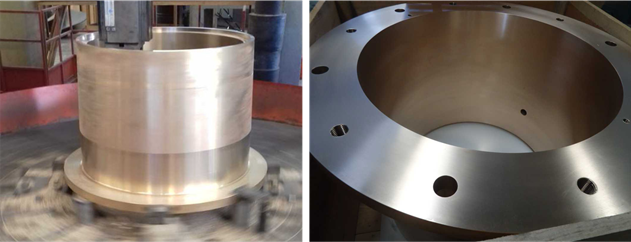

At Rice Foundry we have specialized in reverse engineering. This tool is used when there are no dimensions and only the sample product is available. The procedure is accomplished through

the use of 3D scanner technology, the part is analyzed and digitized in order to obtain a virtual model. The virtual models obtained are useful for many applications, you can compare a

defective model with a functional model and improve the efficiency of the product or correct errors in the design and thus obtain measurements of which they were not accessible with a

great precision of 0.0005".

We do not seek for wholesale, our market are large custom made pieces according to the needs of our clients. Each part is manufactured with the highest quality and durability standards

and endorsed by the ISO 9001:2015 norm and the certifying houses that operate worldwide, such as DNV-GL, ABS, ClassNK, Lloyd's Register, CCS, RINA and Bureau Veritas. Likewise, we

provide technical advice for any questions, whether casting for the manufacture of bronze parts is required, precision machining, calculation, dimensions, geometries or reference

measurements.

|

|

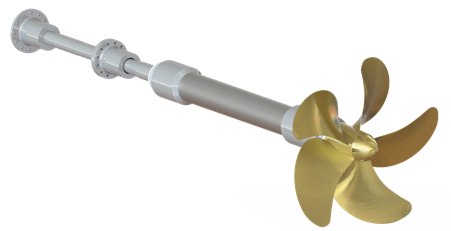

MARINE PROPELLERS

In the process of designing a propeller, a wide scope of vision is required of what needs to be accomplished, what type of vessel it is intended for, type of hull and external factors

that directly involve the ship, such as the time it has been in service, machine wear, repairs, etc. Information not taken properly or poorly documented can lead to errors in decision

making, so we always look for a solid foundation to be clear about the result that is intended to be achieved, whether it is obtaining the bollard pull or reaching a desired speed.

At RICE Propulsion the internal process for the design of propellers is carried out by means of an evaluation of the general measurements of the boat, composition of the machinery,

power, transmission, type of service, maximum distances for the propeller diameter, etc. Although shape lines or axis arrangements are useful, it is important to know the differences

between them and be able to evaluate them. We also have a questionnaire that makes it easy for customers to transfer vital information to design the correct propeller for the boat.

------------------------------------------------Click HERE to visit our WEB Questionnaire------------------------------------------------

|

|

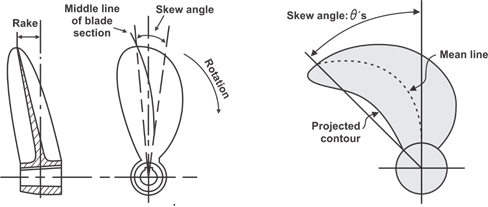

The design of each propeller can vary according to its manufacturer, it can change its shape, skew (angle), rake (launch), if it is fixed, variable or controllable pitch. We use a 3D

design software, which is used to create the part modeling based on RICE designs or provided by the client. This allows us to visualize its characteristics and to be able to create a

model from this software for its casting. Attached is a previous calculation that reviews the speed that the boat could reach. A basic tool to achieve this is a numerical control

software, designed to calculate a speed estimate based on its power, length and draft. Having obtained this basis, the most efficient propeller is calculated for the function that the

boat is going to perform, be it for a tug, catamaran, speedboat, yacht, fishing boat, etc.

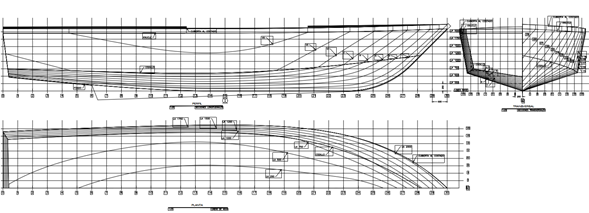

For the drawing and layouts the most used and versatile is a computer-aided software for 2D drawings, necessary to visualize propulsion systems, as well as all the details of the boat

such as the arrangements of axles, couplings, horn tube, flying buttresses and any detail of coupling for seals either oil lubrication or water lubricated. Regarding to the preparation

of the propellers, it is necessary to visualize the position where it will be mounted, tolerances to be verified between the hull shoe and the keel, if it will have a nozzle, how will

the shape and positioning be or if it has enough space to be placed. Each of these criterias must be considered in the design of a propeller.

At RICE Foundries, tolerances are very important, both in distance evaluation and in manufacturing, for example, the estimation of maximum thicknesses (ABS rules), dimensions,

tolerances in the blade, ropes and finish (International Standard ISO 484/2 ), machined from hub and standard bores (SAE-J755).

At RICE Foundries, tolerances are very important, both in distance evaluation and in manufacturing, for example, the estimation of maximum thicknesses (ABS rules), dimensions,

tolerances in the blade, ropes and finish (International Standard ISO 484/2 ), machined from hub and standard bores (SAE-J755).

To provide the best services to our clients, we have a technical team which addresses and proposes solutions with the aim of delivering a final job of quality and durability, in

addition to creating a close and fluid communication to be able to resolve any questions that arise in a future.

|