|

There

are more than 50 types of BRONZE ALLOYS where the main component within it is copper and secondly tin.

Bronze is all copper and tin alloy, in which copper constitutes 60% and tin appears in a proportion of 3% - 20%, to which it can vary in both minerals depending

on the need and the aggregation of others more to modify the physical and mechanical properties of the alloys, as the case may be.

Bronze was the first alloy of importance obtained by man and gives its name to the Bronze Age. For millennia it was the basic alloy for the manufacture of

weapons and utensils, and goldsmiths from all eras have used it in jewelry, medals and sculpture. Coins minted with bronze alloys had a relevant role in trade.

As mentioned above, copper is part of a very high amount of alloys that generally have better mechanical properties, although they have a lower electrical conductivity.

The most important are known as bronzes and brass. On the other hand, copper is a durable metal because it can be recycled almost unlimited times without losing its

mechanical properties.

Within our foundry services we have the following alloys, which according to more than 60 years of experience of Rice Foundries, has allowed us to meet the different

needs of the naval sector, as well as industrial and decoration. Each of the pieces custom made for each client.

In the market attending industrial and naval business, the use of different types of bronze is very common, such as ALUMINUM BRONZE bushings, consisting of 90% copper

and 10% aluminum, thus mimicking the appearance of the gold and for this reason is used for artistic works as well as for decoration pieces, and particularly in the

industrial field, in bushings, aircraft engine valve seats, corrosion resistant parts, worm gears, pickling hooks, baskets and agitators, as well as propellers, impellers,

stator segments, safety tools, welding rods, valves, smelting of pumps that regularly have contact with salt water.

Below are two images of this alloy:

|

Aluminum bronze bushing

Aluminum bronze propeller, better known as NiBrAl

|

|

BRONZE TIN: This type of bronze is made up of 30% tin and 0.5% phosphorus, the rest of copper to reinforce the hardness and strength properties of the alloy,

which is highly recommended for gears and manufacturing engines that are regularly subjected to high temperatures and strong pressures, clearly the rest of the alloy is

copper. Among the pieces that we can find of this alloy are valves, power couplings, gears, crowns, steam fittings. It is also used for sacrificial parts that require a

fine bronze such as bearings, bushings, piston rings, valve components, seals, steam conductive connections, high-speed and high-pressure bearings, pumps, impellers,

applications of corrosion resistance, closed forging foundries.

Depending on the elements and the aggregation of lead, there may be variations in the fittings.

Tin bronze bushing in machining process

Tin bronze bushing in machining process

|

|

MANGANESE BRONZE: Manganese bronze (high strength yellow brass) combines high tensile strength and high elastic limit with relatively good corrosion resistance. This group of

alloys is basically made of copper and zinc to which aluminum is added, which is the main fortifier, in addition to manganese and iron that act as grain refiners; tin and nickel are

mainly added to increase corrosion resistance; Sometimes lead is added to improve machinability. The most commonly used parts of this alloy are: propellers, impellers, stator segments,

safety tools, welding rods, valves, pumps casting.

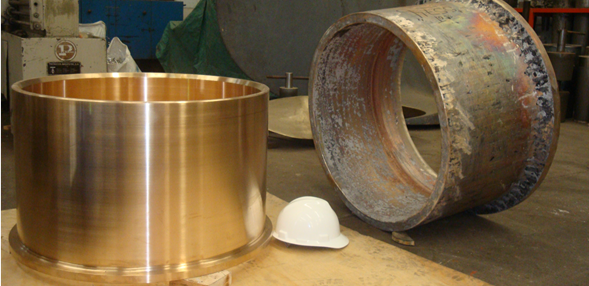

Replica of a bushing for the mining industry

Replica of a bushing for the mining industry

|

|

Below we show a detailed table of our alloys with their respective characteristics and applications.

|

TABLE ALLOYS AND MATERIALS |

|

FAMILY |

CDA |

ASTM |

SAE |

EFFORT STRESS (ksi) |

Yield point (ksi) |

% Elongation at 50 mm |

APPLICATIONS |

|

BRASS RED |

836 |

B62,B145-4A |

40 |

30 |

14 |

20 |

Valves, flanges, pipe fittings, plumbing fittings, cast iron pump, water pump impellers and housing, ornamental accessories, small gears. |

|

MANGANESE BRONZE |

865 |

B147-8A |

-- |

65 |

25 |

20 |

Machine parts with hardness requirement, lever arms, valve stems, gears. |

|

BRONZE TIN |

903 |

B143-1B |

620 |

40 |

18 |

20 |

Bearings, bushings, pump impellers, piston rings, valve components, seals, conductive connections steam gears. |

|

BRONZE TIN |

905 |

B22-D, B143-1A |

62 |

40 |

18 |

20 |

Bearings, bushings, pump impellers, piston rings, valve components, conductive connections steam gears. |

|

BRONZE TIN LEAD |

926 |

B22-D,B143-1A |

62 |

40 |

18 |

20 |

Bearings, bushings, pump impellers, piston rings, valve components, conductive connections steam gears. |

|

BRONZE TIN LEAD |

927 |

-- |

63 |

35 |

21 |

10 |

Bearings, bushings, pump impellers, piston rings, valve components, conductive connections steam gears. |

|

BRONZE TIN A HIGH LEAD |

932 |

B144-3B |

660 |

30 |

14 |

12 |

Bearings and bushings general use. |

|

BRONZE TIN A HIGH LEAD |

937 |

B144-3A |

64 |

25 |

12 |

8 |

Mounted high speed and high pressure pumps, impellers, applications corrosion resistance, foundries closed forging. |

|

BRONZE TIN A HIGH LEAD |

938 |

B144-3D |

67 |

25 |

14 |

10 |

Bearings for general use and moderate pressures, impellers and pump housings for use of acid mine water. |

|

BRONZE TIN A HIGH LEAD |

939 |

-- |

67 |

25 |

16 |

5 |

Continuous casting, bearings for general use, pump housings and impellers for mine water. |

|

BRONZE ALUMINUM |

955 |

B148-9D |

-- |

90 |

40 |

6 |

Guides and valve seats aircraft engine, resistant to corrosion parts, bushings, gear worm, pickled hooks, baskets and agitators. |

|

ALUMINUM BRONZE MANGANESE |

957 |

B148-9F |

-- |

90 |

40 |

20 |

Propellers, impellers, stators segments, security tools, welding rods, valves, pumps casting. |

|

BRONZE ALUMINUM |

958 |

-- |

-- |

85 |

35 |

18 |

Maces propellers, blades and other parts in contact with salt water. |

|