|

Dynamic balance is the art of compensating and redistributing mass, due to the effect produced by

the decompensation of the masses due to errors generated in the manufacturing or machining of rotating machines.

Dynamic balance is the art of compensating and redistributing mass, due to the effect produced by

the decompensation of the masses due to errors generated in the manufacturing or machining of rotating machines.

What is the unbalance?

It is said that a piece is unbalanced when its center of mass (center of gravity) does not match its geometric center.

Under what standard should be balanced?

The norm commonly used to assess the severity of the imbalance is ISO 1940. Every rotating part, even if it has been made keeping the greatest care, always presents an imbalance. This

residual imbalance, depending on the type of piece, its weight and its speed, must be less than the maximum imbalance set by the standard, some of the degrees of imbalance established by

the norm according to its use or application are the following:

|

| BALANCING DEGREE |

APLICATION |

| G-2.5 mm/s |

- Components of gas or steam turbines.

- Turbo-generator rotors.

- Turbo-compressors.

- Machine tools.

- Small electrical armor.

- Turbo-pumps.

|

| G-6.3 mm/s |

- Components of process machines.

- Main turbines (Merchant Marine).

- Centrifugal drums.

- Fans.

- Aeronautical Assemblies.

- Turbine rotors.

- Pulleys.

- Pump impellers.

- Electric armor.

- Components.

|

| G-16 mm/s |

- Impellers shafts (propellers, cardan) with special requirements.

- Crusher parts.

- Farm equipment.

- Individual engine components (diesel, gasoline) for cars, trucks and locomotives.

- Machinery crankshafts with 6 or more cylinders for special requirements.

|

| G-40 mm/s |

- Car tires, wheels.

- Stretch mounting crankshafts of 4-stroke engines or more cylinders.

- Car, truck or locomotive engine crankshafts.

|

| G-0.4 mm/s |

- Spindles.

- Discs.

- Gyroscopes.

|

| G-1 mm/s |

- Recorder and phonograph motors.

- AC liner motors.

- Small electrical armor with special requirements.

|

|

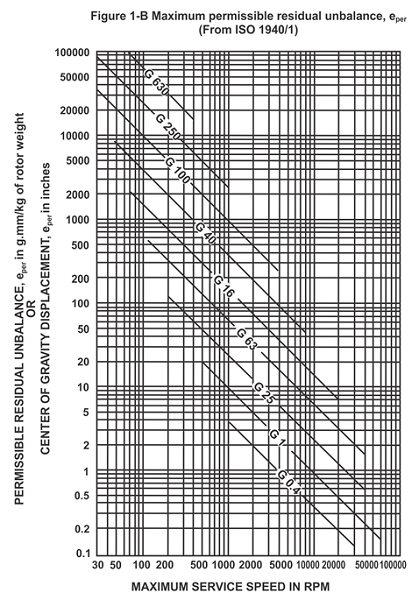

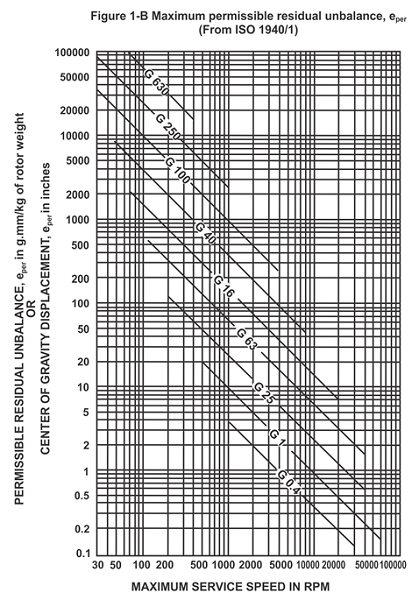

The ISO 1940 norm provides the following table, where the maximum allowable residual imbalance can be obtained by knowing the degree and maximum service speed of the workpiece

to be balanced.

|

|

What for is the dynamic balancing in propellers

A dynamically balanced propeller helps reduce vibrations and noise caused by it, and also improves the efficiency of the propulsion system in terms of maneuverability and

fuel consumption.

What kind of propellers need dynamic balance?

According to the American Bureau of shipping (ABS) sorting house, dynamic balancing is necessary on propellers that work above 500 rpm. In Rice foundries we have the

experience and the necessary equipment for the elaboration of dynamic balancing for propellers up to 80" in diameter.

|

|